OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker

OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker Aluminium Tag

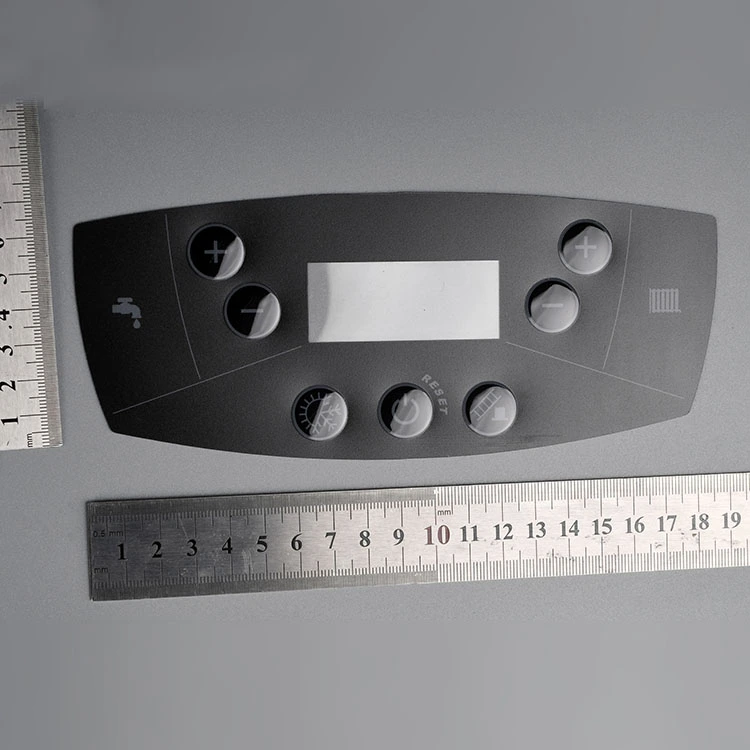

Aluminium Tag Rice Cooker Decoration Front Panel

Rice Cooker Decoration Front Panel Electroform Metal Label Nickel Logo Sticker

Electroform Metal Label Nickel Logo Sticker 3D Metal Plate Sticker

3D Metal Plate Sticker 3D ABS Plastic Brands logo

3D ABS Plastic Brands logo ABS Plastic 3D Embossed logo

ABS Plastic 3D Embossed logo Machine 3D ABS Plastic Logo

Machine 3D ABS Plastic Logo Metal Sticker Logo

Metal Sticker Logo Waterproof 3D soft label

Waterproof 3D soft label Embossed 3D soft label

Embossed 3D soft label 3D Soft Plastic Label Sticker

3D Soft Plastic Label Sticker

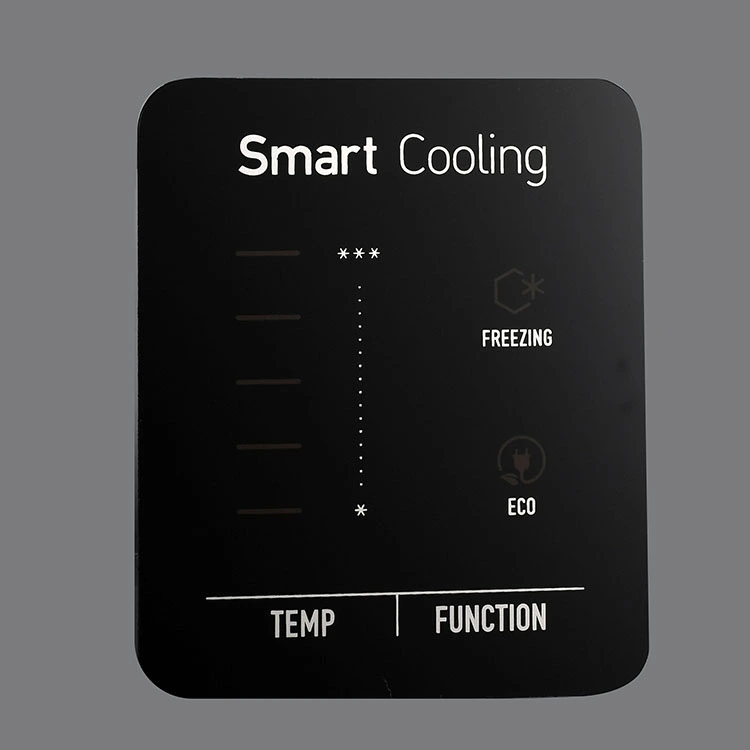

Plastic Injection in Mold Decoration Panel

Minghong Technology is a first-class advanced Plastic Injection in Mold Decoration Panel supplier in China. We provide complete manufacturing solutions covering all aspects such as material identification, mold manufacturing, parts processing, finishing and final inspection. Our team of international manufacturing experts is committed to providing you with the highest level of professional injection molding service support, no matter the size or complexity!

Send InquiryMinghong Technology is committed to creating the highest quality products and components for customers, providing customers with competitive Plastic Injection in Mold Decoration Panel, including prototyping, mass production, small batch production, 3D printing, mold manufacturing and injection molding.

With more than 20 years of rich production experience in the Panel industry, it has the world's most advanced production equipment, testing equipment, thousand-level dust-free painting workshop and assembly workshop, 9 domestic advanced assembly line equipment and 6 equipment wiring. Using the world's fastest and easiest mold making method, mold making can be completed in seven days and mass production can start in twelve days, which greatly shortens the customer's production cycle, reduces mold opening risks, improves mold quality, and saves development costs.

Detail:

| Material | PET, PC, PVC, acrylic, stainless steel, aluminum 3M adhesive and so on |

| Technology | Silk screen printing, UV printing, stamping, laser cutting, CNC carving |

| Thickness | 0.1-8mm |

| Color | Transparent, white, glossy, brushed, matt, colorful |

| Performance |

Plastic:72H temperature test -20℃∽+60℃ metal:24H salt spray test, 72H temperature test -20℃∽+100℃ Holding force test:100H with weight 500g |

| Scope | Household appliances, furniture, car, electric bicycle, digital products, bath products, mechanical equipment etc |

| Delivery date | Sample time:7-15days Production time:10-15days for MOQ 1000pcs |

What is injection molding?

Injection molding is the most common production method in industrial manufacturing. Most of the plastic products we come into contact with on a daily basis are processed in this way, from toys, car parts, bottles to mobile phone cases. So, how does injection molding work?

At a certain temperature, the heated and molten resin raw material is injected into the mold cavity by high pressure, and the molded product is formed after cooling and solidification.

Types of injection molding processes

We offer a variety of different molding processing methods, such as plastic injection molding, liquid silicone rubber molding, overmolding and insert molding. With our advanced production capabilities and more than 20 years of team experience, we can undertake various types of molding projects, covering metal, plastic and silicone materials, regardless of the scale and difficulty of the project.

Flexible application

Plastic Injection in Mold Decoration Panel has a wide range of applications, ranging from the production of complex components in the automotive industry to medical devices. These processes can also be used to produce products with stronger mechanical properties, longer service life and more beautiful appearance.

Material and design advantages

The combination of different materials in Plastic Injection in Mold Decoration Panel can achieve innovative design and performance improvement. For example, depending on the plastic chosen, soft components can enhance grip, while hard components can help improve the structural integrity of the product.