OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker

OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker Aluminium Tag

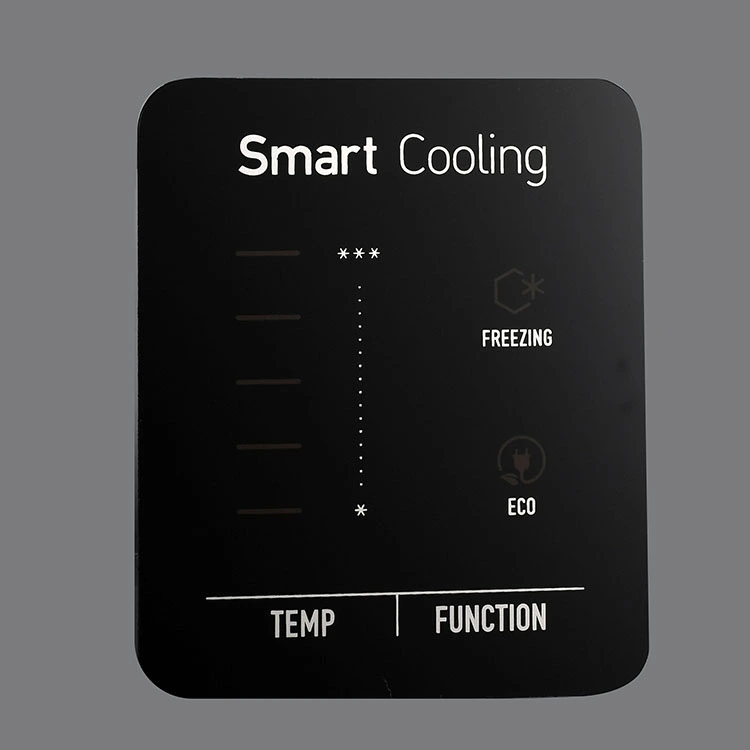

Aluminium Tag Rice Cooker Decoration Front Panel

Rice Cooker Decoration Front Panel 3D Metal Plate Sticker

3D Metal Plate Sticker Electroform Metal Label Nickel Logo Sticker

Electroform Metal Label Nickel Logo Sticker 3D ABS Plastic Brands logo

3D ABS Plastic Brands logo ABS Plastic 3D Embossed logo

ABS Plastic 3D Embossed logo Machine 3D ABS Plastic Logo

Machine 3D ABS Plastic Logo Metal Sticker Logo

Metal Sticker Logo Waterproof 3D soft label

Waterproof 3D soft label Embossed 3D soft label

Embossed 3D soft label 3D Soft Plastic Label Sticker

3D Soft Plastic Label Sticker

Metal Label with Logo

Wenzhou Minghong Electroplating Technology Co., Ltd. produces metal labels with logos made of various metals such as aluminum, stainless steel, zinc alloy, etc. Suitable for various household appliances, mechanical equipment, kitchen and bathroom products, and electric vehicles. Combining different processes such as screen printing, stamping, anodizing, etc., can fully showcase your company's brand image and product texture.

Send InquiryMetal Label with Logo is Minghong Tachnology's flagship customized product, widely used in fields such as electrical appliances, mechanical equipment, kitchen and bathroom products, and electric vehicles. The company has 13 years of industry experience and integrates design, injection molding, electroplating, spraying, and surface treatment, possessing strong intelligent manufacturing and customization capabilities. Relying on three electroplating lines, two spraying lines, and a 2500 square meter dust-free workshop, Minghong Tachnology focuses on creating high quality, durable, and aesthetically pleasing personalized brand nameplates for customers.

Metal label with Logo Detail:

| Material | Aluminum, zinc alloy, stainless steel, 3M adhesive |

| Technology | Silk screen printing, UV printing, stamping, die-casting and so on |

| Thickness | 0.3-1.5mm |

| Color | Glossy silver or gold, matt, brushed silver or gold and so on |

| Performance |

24H salt spray test, temperature test -20℃∽+100℃, Holding force test:100H with weight 500g Holding force test:100H with weight 500g |

| Scope | Household appliances, furniture, car, electric bicycle, digital products, bath products, mechanical equipment, signboard etc |

| Delivery date | Sample time:7-10days Production time:7-10days for MOQ 1000pcs |

Technological advantages:

Multiple electroplating and surface treatments (bright light, wire drawing, sandblasting, imitation gold, etc. )

High precision CNC engraving and laser marking

Environmentally friendly process, compliant with EU RoHS standards

Strong adhesion, corrosion resistance, scratch and wear resistance

Why Choose Minghong Tachnology?

Minghong Tachnology has independently built intelligent manufacturing workshops equipped with 120-250 ton injection molding machines, 500-1200 ton hydraulic presses, three electroplating production lines, two spraying lines, CNC machining centers, laser engraving equipment, etc. The delivery time for large orders has been stable.

Minghong Tachnology has 8 senior R&D designers and 20 technical backbones, who can provide customers with production design solutions from design sampling, mold development to mass production.