OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker

OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker Aluminium Tag

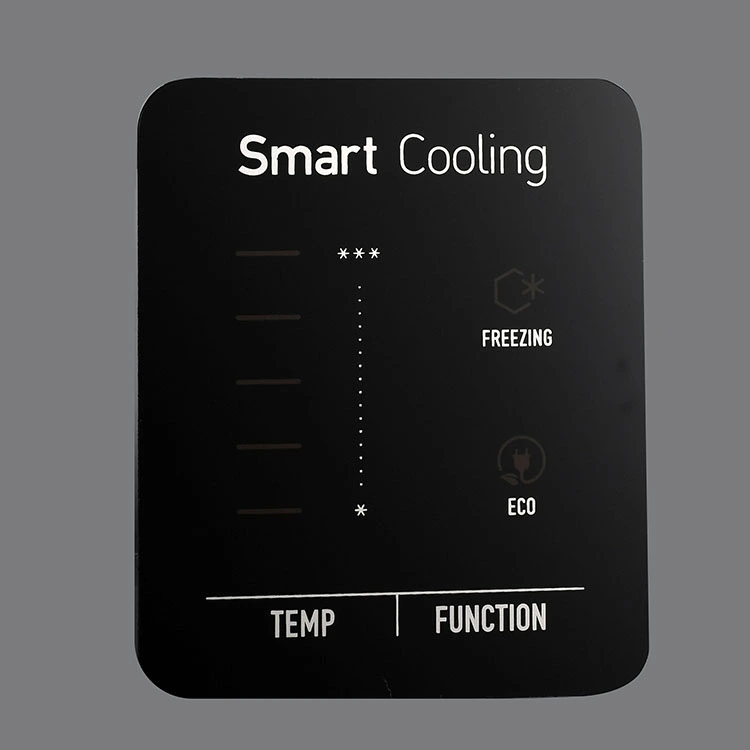

Aluminium Tag Rice Cooker Decoration Front Panel

Rice Cooker Decoration Front Panel 3D Metal Plate Sticker

3D Metal Plate Sticker Electroform Metal Label Nickel Logo Sticker

Electroform Metal Label Nickel Logo Sticker 3D ABS Plastic Brands logo

3D ABS Plastic Brands logo ABS Plastic 3D Embossed logo

ABS Plastic 3D Embossed logo Machine 3D ABS Plastic Logo

Machine 3D ABS Plastic Logo Metal Sticker Logo

Metal Sticker Logo Waterproof 3D soft label

Waterproof 3D soft label Embossed 3D soft label

Embossed 3D soft label 3D Soft Plastic Label Sticker

3D Soft Plastic Label Sticker

In Mold Decoration on Plastic Injection Parts

Minghong Technology offers cost-effective and durable in-Mold Decoration on Plastic Injection Parts, as well as analysis of existing products. The product is optically analyzed and optimally optically calculated by our own optical laboratory. Labels are printed using screen printing technology. You will get a very satisfactory product! If you have any other special requirements, just tell us and we will solve it in the first time!

Send InquiryCompared with traditional control panels, the significant advantage of using Minghong Technology's high quality in-Mold Decoration on Plastic Injection Parts is that it can significantly affect the shape of the finished product. Although printing directly on the plastic injection mold is efficient and durable, it is limited to flat surfaces, which to some extent limits the design options of electronic devices. IMD technology solves this problem: customized labels are integrated with the molded parts, thus expanding the possibilities of shape design.

Detail:

| Material |

PET and ABS |

| Technology |

Silk screen printing,UV printing, injection, electroplating |

| Thickness | 30-50mm |

| Color |

Spot color ,silver , gold ,brushed effect |

| Performance |

72H temperature test -20℃∽+80℃ |

| Scope | Indoor household appliances,Digital products,mechanical equipment,Etc |

| Delivery date |

Sample time:20-30days Production time:15-20days for MOQ 1000pcs |

Feature:

Development services in mechanical, electrical and electronic fields

IMD plastic processing in cleanroom environments, including UV drying and component cleaning

Assembly services from functional films to complete assemblies

System understanding

Extensive development expertise

In-depth knowledge of processes

Process and cost efficiencies through automation

Label printing using screen printing technology.

In-mold decoration (IMD) is a modern method of decorating electronic devices during the molding of plastic parts, including control panels. This solution has been applied in many industries and is becoming increasingly popular. In today's article, I will focus on analyzing the key features of this technology and the opportunities it brings to manufacturers in the home appliance, consumer electronics and automotive industries.

One of the major advantages of IMD technology is the ability to customize parts of different shapes, which are ideal for use as decorative or functional parts of electronic devices. Minghong Technology has currently applied this technology to front panels and control panels in industries such as home appliances, consumer electronics and automotive.

IMD technology can permanently bond pre-printed screen-printed labels to device parts, thereby improving the durability of the device and enhancing the appearance of the device. This eliminates the need for external labels, which would be exposed to mechanical damage during daily use of electronic devices.