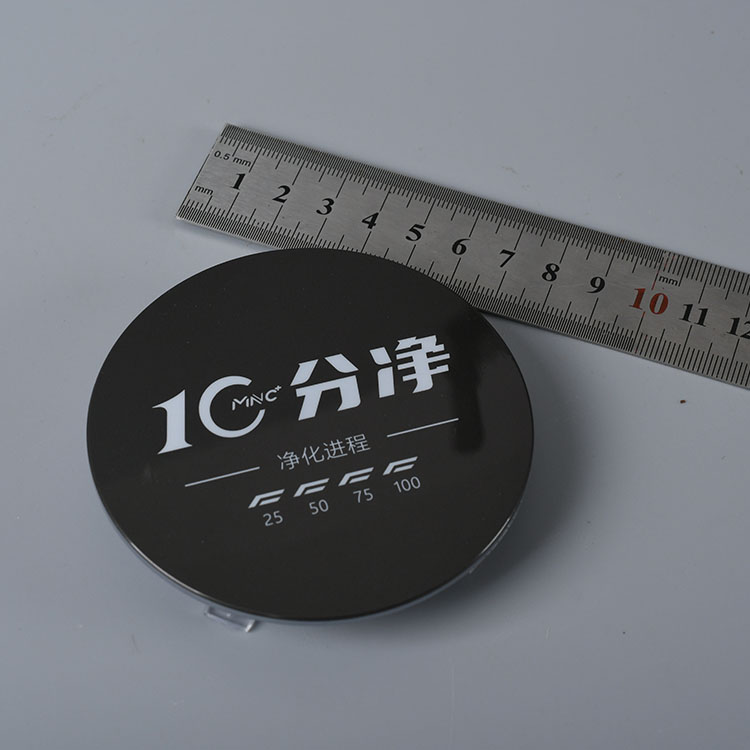

OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker

OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker Aluminium Tag

Aluminium Tag Rice Cooker Decoration Front Panel

Rice Cooker Decoration Front Panel 3D Metal Plate Sticker

3D Metal Plate Sticker Electroform Metal Label Nickel Logo Sticker

Electroform Metal Label Nickel Logo Sticker 3D ABS Plastic Brands logo

3D ABS Plastic Brands logo ABS Plastic 3D Embossed logo

ABS Plastic 3D Embossed logo Machine 3D ABS Plastic Logo

Machine 3D ABS Plastic Logo Metal Sticker Logo

Metal Sticker Logo Waterproof 3D soft label

Waterproof 3D soft label Embossed 3D soft label

Embossed 3D soft label 3D Soft Plastic Label Sticker

3D Soft Plastic Label Sticker

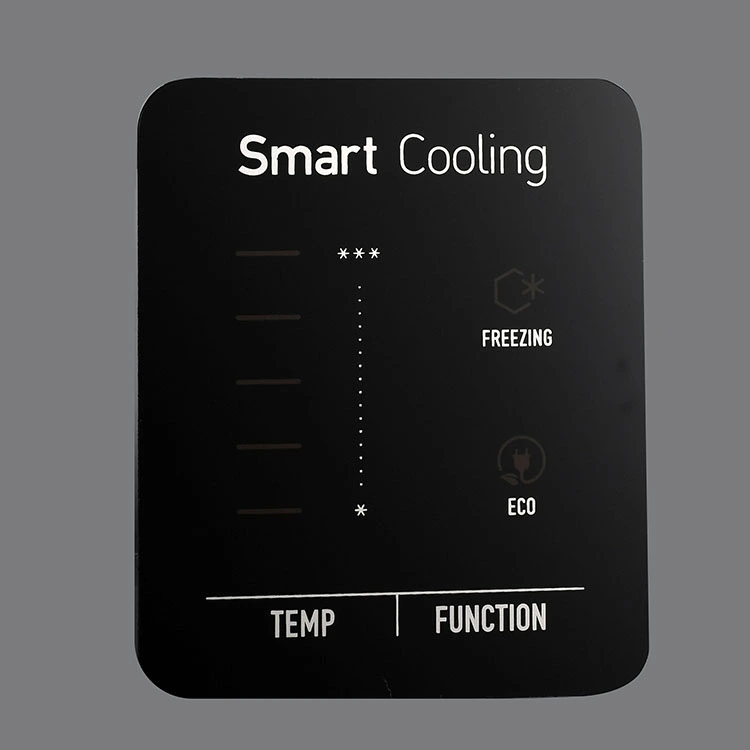

In Mold Decoration for Home Appliance

Minghong Technology offers high quality, mostly backlit in Mold Decoration for Home Appliance with IMD (In Mold Decoration) technology. We use our experience and vertical integration in the field of plastic injection molding and light control to meet current market needs. With machine technology made in China and partners for decorative and functional film technology, we meet our customers' needs at the highest level.

Send InquiryProduct design determines whether customers are willing to take a second look. Minghong Technology's in Mold Decoration for Home Appliance makes your product surface magically attractive to customers in just one step. IMD gives you great freedom in design and touch, while effectively protecting against external influences such as scratches, abrasions, sun and moisture. In addition, the process reduces the carbon footprint by 70%!

Detail:

| Material |

PET and ABS |

| Technology |

Silk screen printing,UV printing, injection, electroplating |

| Thickness | 30-50mm |

| Color |

Spot color ,silver , gold ,brushed effect |

| Performance |

72H temperature test -20℃∽+80℃ |

| Scope | Indoor household appliances,Digital products,mechanical equipment,Etc |

| Delivery date |

Sample time:20-30days Production time:15-20days for MOQ 1000pcs |

In Mold Decoration Process:

Foil feeders such as IMD SI DUO are installed on the injection molding machine to ensure that the decorative foil is precisely aligned.

in Mold Decoration for Home Appliance is pressed onto the mold cavity wall by the injection molding compound. Due to the heating of the mold, the decorative pattern is detached from the carrier and transferred to the component by a strong adhesive.

With this process, individual motifs with a length of more than 1,000 millimeters can be applied with extreme precision.

Key benefits at a glance:

70% reduction in carbon footprint

Economic integration into your value chain

in Mold Decoration for Home Appliance is also suitable for complex geometries, such as curved displays or 3D geometries

Soft touch surfaces enable a wide range of haptic effects. This gives you an additional competitive advantage, as tactile design is increasingly becoming a distinctive feature.

Consistent quality even in large series.

Radiolucent, partial or full surfaces, day/night design, frameless design or mood lighting

Metalized decorations that do not require shielding of Wi-Fi, Bluetooth or wireless connections. On request, we use non-shielding non conductive vacuum metallization (NCVM) films.

in Mold Decoration for Home Appliance combines decorative and touch functions in one efficient process. We apply the transparent, conductive backing material for touch sensors to the back of the component and apply the decorative design to the front during the injection molding process. In this way, we transform your ideas into surprising surface designs, including functional touch features.

We take on new challenges, even for components with the highest demands on design and functionality.