OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker

OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker Aluminium Tag

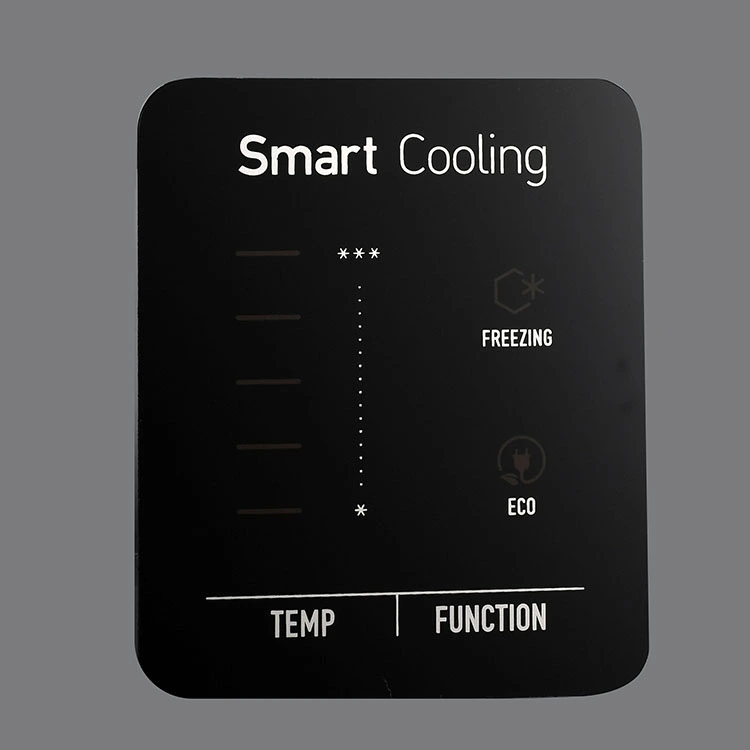

Aluminium Tag Rice Cooker Decoration Front Panel

Rice Cooker Decoration Front Panel Electroform Metal Label Nickel Logo Sticker

Electroform Metal Label Nickel Logo Sticker 3D Metal Plate Sticker

3D Metal Plate Sticker 3D ABS Plastic Brands logo

3D ABS Plastic Brands logo ABS Plastic 3D Embossed logo

ABS Plastic 3D Embossed logo Machine 3D ABS Plastic Logo

Machine 3D ABS Plastic Logo Metal Sticker Logo

Metal Sticker Logo Waterproof 3D soft label

Waterproof 3D soft label Embossed 3D soft label

Embossed 3D soft label 3D Soft Plastic Label Sticker

3D Soft Plastic Label Sticker

IMD Parts for Home Appliance

Minghong Technology is the first professional IMD Parts for Home Appliance manufacturer in Wenzhou. The company was founded in 2010. The industrial park covers an area of more than 30,000 square meters. It has a high-precision dust-free workshop and focuses on supporting high-speed rail, home appliances, automobiles, and products. From engineering research and development to mold making, diaphragm printing, diaphragm molding, diaphragm injection molding, inspection and packaging, it has a complete process flow.

Send InquiryMinghong Technology is committed to the production and sale of IMD Parts for Home Appliance. Minghong Technology's employees firmly believe that the function and appearance of their high-end home appliances will benefit from IMD technology. IMD technology makes a variety of designs possible, even including metallization. For home appliances, IMD technology is particularly important for its built-in surface protection function. The surface is easy to clean and the decorative materials are resistant to detergents or moisture erosion. Always adhere to the business philosophy of creating value for customers, and move towards the corporate vision of becoming a company respected by the society, trusted by customers, and happy employees

Detail:

| Material |

PET and ABS |

| Technology |

Silk screen printing,UV printing, injection, electroplating |

| Thickness | 30-50mm |

| Color |

Spot color ,silver , gold ,brushed effect |

| Performance |

72H temperature test -20℃∽+80℃ |

| Scope | Indoor household appliances,Digital products,mechanical equipment,Etc |

| Delivery date |

Sample time:20-30days Production time:15-20days for MOQ 1000pcs |

In Mold Decoration Process:

IMD Parts for Home Appliance uses surface-coated PET film as a carrier, prints ink pattern layer, adhesive and ink curing on the printing surface, and then heats and bakes, performs hot pressing molding and trimming. The molded PET film is fed into the injection mold cavity by manual or robotic arms, filled with plastic, and the adhesive is melted at high temperature, so that the PET film is bonded to the ink pattern layer and forms a whole with the plastic.

IMD technology brings manufacturing and economic advantages:

The economic advantages of the IMD process are unquestionable. Oven control panels are usually made of painted or pure aluminum. Alternatively, additional processing is required to obtain the desired surface appearance. Manufacturing processes such as painting or galvanizing are mostly carried out in Asia or Eastern Europe; these processes are costly and have a rather negative impact on the environment. IMD not only enables injection molding and decoration to be completed in one step, but also applies to recycled plastic materials and brings the decoration process in-house, making it more efficient and sustainable.