OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker

OEM Electroplating Embossed Custom Tag Nickel Logo Metal Label Sticker Aluminium Tag

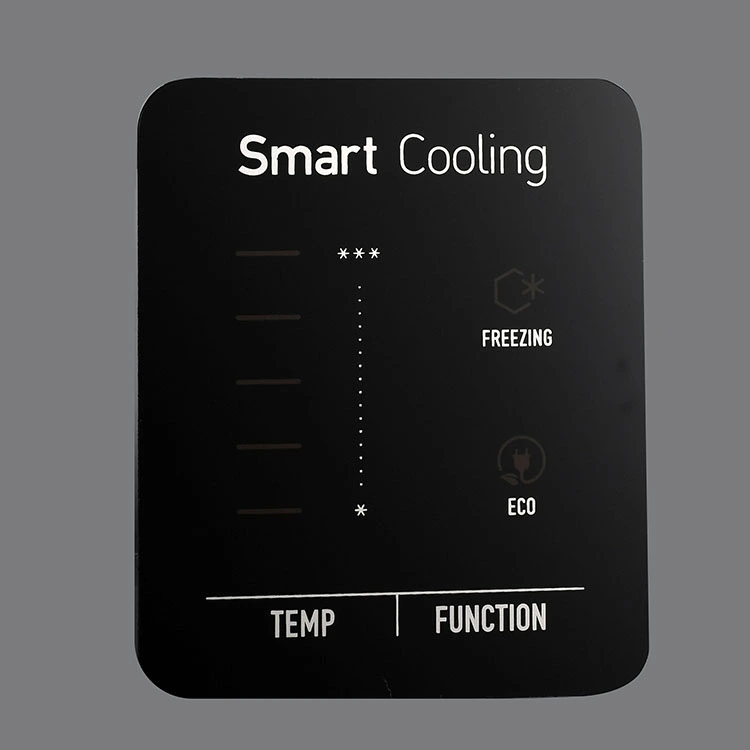

Aluminium Tag Rice Cooker Decoration Front Panel

Rice Cooker Decoration Front Panel 3D Metal Plate Sticker

3D Metal Plate Sticker Electroform Metal Label Nickel Logo Sticker

Electroform Metal Label Nickel Logo Sticker 3D ABS Plastic Brands logo

3D ABS Plastic Brands logo ABS Plastic 3D Embossed logo

ABS Plastic 3D Embossed logo Machine 3D ABS Plastic Logo

Machine 3D ABS Plastic Logo Metal Sticker Logo

Metal Sticker Logo Waterproof 3D soft label

Waterproof 3D soft label Embossed 3D soft label

Embossed 3D soft label 3D Soft Plastic Label Sticker

3D Soft Plastic Label Sticker

Electroforming Nickel Metal Sticker Logo Label

Welcome to Minghong Technology, the first choice for custom metal stickers! Based in China, we specialize in a variety of metal stickers, including Electroforming Nickel Metal Sticker Logo Label, 3D nickel metal stickers, stainless steel metal stickers, aluminum plate stickers, and electroformed pet stickers. Whether you need personalized customization or bulk orders, we provide global shipping services and are promised to creating high quality, one of a kind custom metal stickers for you. Let our custom metal stickers add luster to your brand image and design projects!

Send InquiryIn the field of labels, Minghong Technology's durable Electroforming Nickel Metal Sticker Logo Label is made through multiple stages to create a product that can withstand harsh environments. This article will take a deep dive into the production process of 3D electroformed nickel labels, exploring each step in detail and highlighting its various applications.

Design and Preparation

The first step in making an Electroforming Nickel Metal Sticker Logo Label is to design the label itself. This requires creating a digital design that meets the customer's specifications, taking into account the size, shape, and complexity of the label. Once the design is completed, it is printed onto a special film that acts as a mold for the label. This film is critical in the electroforming process as it provides a template for the nickel ions to be deposited.

The design should be precise and detailed as any imperfections will be reflected in the final product. The film should also be of high quality with a smooth surface so that the nickel ions are deposited evenly. The design and preparation phases lay the foundation for the totally production process and are critical steps in making high quality labels.

Substrate Preparation

Before the electroforming process can begin, the substrate must be prepared. This includes thoroughly cleaning the substrate to make there are no contaminants that could interfere with the electroforming process. Solvents or abrasives can be used to remove any dirt or debris, leaving the substrate surface smooth and free of imperfections.

The substrate material can vary, but is typically a metal or plastic surface that provides a solid base for the label. The preparation of the substrate is critical as any imperfections will affect the adhesion of the nickel label, causing it to flake or peel over time.

Nickel Plating

The actual label creation process takes place in the nickel plating process. A copper mold with the 3D design is placed on the substrate and the entire assembly is then immersed in a bath of electroforming way. An electric current is passed through the bath of solution, causing the nickel ions to be deposited on the substrate. The nickel ions are deposited layer by layer, conforming to the shape of the pattern on the copper mold.

This process can take anywhere from a few hours to a few days, depending on the size and complexity of the label. The nickel plating process requires careful control of the electroforming method, temperature, and current to allow the nickel ions to be deposited evenly and consistently.

Removing the Copper Mold

When the nickel ions have been deposited to the desired thickness, the copper mold is removed from the substrate. This leaves a raised, three-dimensional label made entirely of nickel. The copper mold is carefully peeled off, taking care not to damage the label or substrate.

The resulting label is an exact replica of the original design, with intricate details and a smooth, shiny surface. The removal of the copper mold marks the completion of the electroforming process, and the label is now ready for finishing and application.

Finishing

The label is then carefully cleaned and polished to remove any residue and give it a smooth, shiny surface. This can be done by hand or with specialized equipment such as an ultrasonic cleaner or polishing wheel.

Detail:

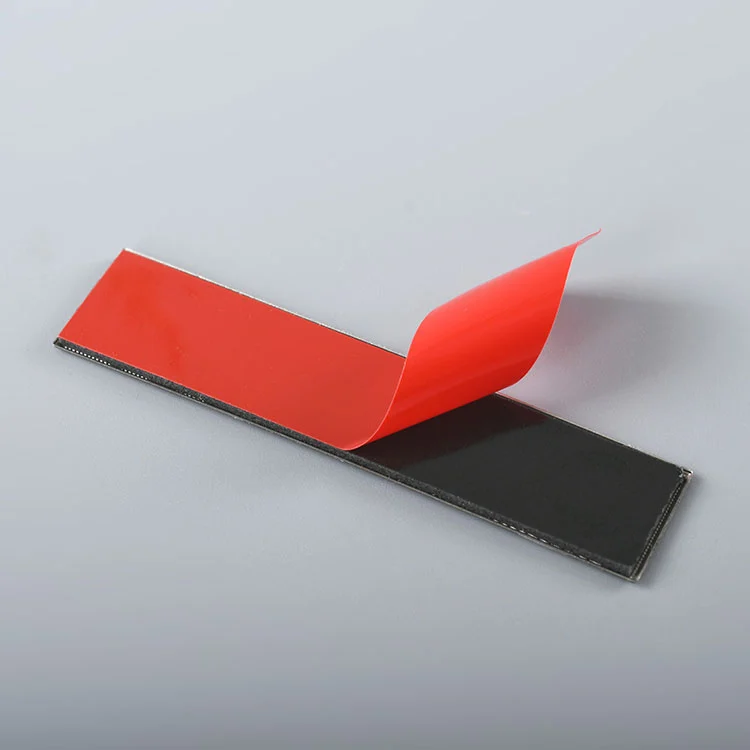

| Material | Nickel, 3M 9448 or 3M VHB |

| Technology | Plating nickel on copper mold, then chroming, fill epoxy, punching, cover glue, packing |

| Thickness | 0.5-3.5mm |

| Color | Glossy silver, gold and black, matt, brushed silver or gold, grid and so on |

| Performance |

72H salt spray test, 72H temperature test -20℃∽+100℃ Holding force test:100H with weight 200g |

| Scope | Household appliances, furniture, car, electric bicycle, digital products, bath products, mechanical equipment etc |

| Delivery date | Sample time:15days Production time:15-20days for MOQ 1000pcs |

Applications:

Electroforming Nickel Metal Sticker Logo Labels are commonly used for product labeling in a variety of industries such as automotive, electronics, and manufacturing. These labels are durable and ideal for use in harsh environments.

For example, automakers can use Electroforming Nickel Metal Sticker Logo Labels to identify engine parts, while electronics companies can use them to mark circuit boards. These labels are resistant to extreme temperatures, chemicals, and physical wear and tear.