What is the electroplating process?

Jul.11, 2025

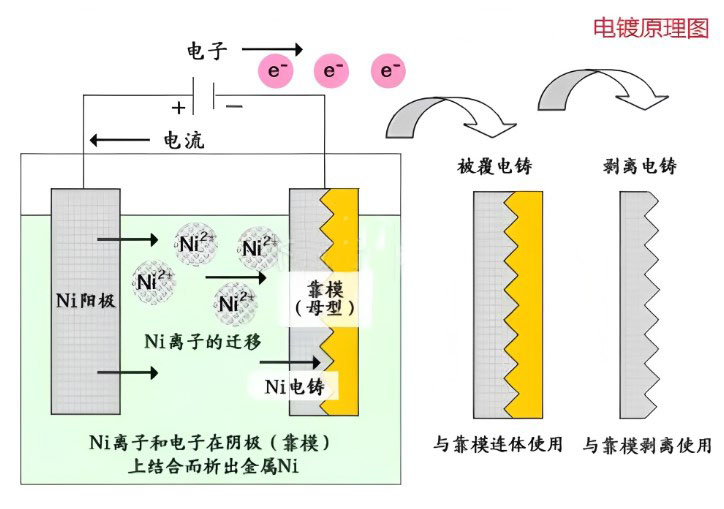

ABS label and electroplating label are electroplated on the surface. so what is the electroplating process?

Electroplating refers to a surface processing method in which the substrate metal to be plated serves as the cathode in a salt solution containing the pre-plated metal. Through electrolysis, the cations of the pre-plated metal in the plating solution deposit on the surface of the substrate metal to form a coating. The performance of the coating is different from that of the base metal and has new characteristics. According to the function of the coating, it can be classified into protective coatings, decorative coatings and other functional coatings. During electroplating, the coating metal or other insoluble materials act as the anode, and the workpiece to be plated serves as the cathode. The cations of the coating metal are reduced on the surface of the workpiece to be plated to form a coating. It can enhance the corrosion resistance of metals (the coating metals are mostly corrosion-resistant metals), increase hardness, prevent wear, improve electrical conductivity, smoothness, heat resistance and surface aesthetics